See.AI™ is our advanced AI vision engine designed to find the root cause of defects in real-time and automatically monitor your operations for safety, compliance, and productivity.

Our AI solution upgrades your existing hardware to meet modern requirements.

Proven Applications & Use Cases

PRODUCTION & QC PROCESS

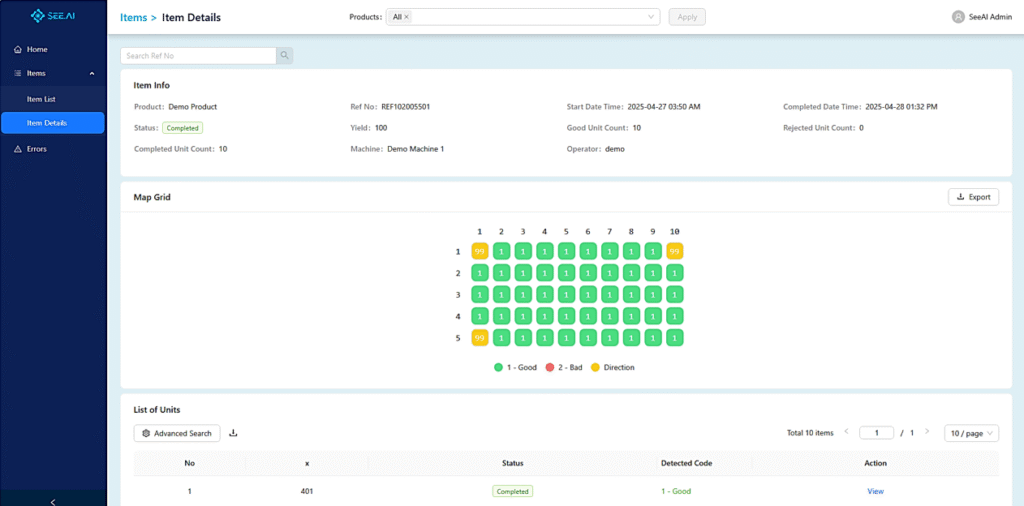

Defect Inspection in Semiconductor Industry

- Problem: Existing AOI machines are over-rejecting, resulting in an average yield rate of 90%. Employing human operators to salvage over-rejected units is costly and less sustainable.

- Solution: See.AI™ augments these existing AOI machines to eliminate over-rejection.

- Key Results: We have achieved a 98.5% new yield rate and an 85% reduction in wastage for a publicly listed semiconductor client.

- Lowered CAPEX: Our AI-powered solution can upgrade your existing cameras, allowing you to meet modern requirements without procuring new hardware.

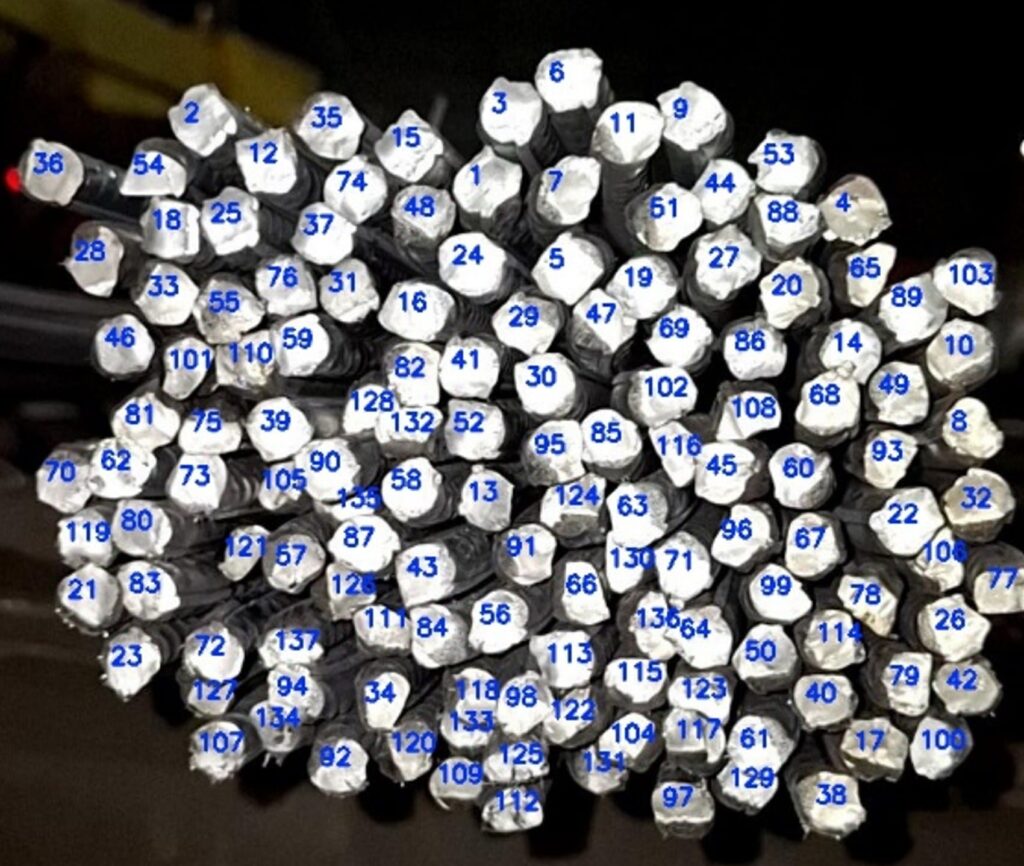

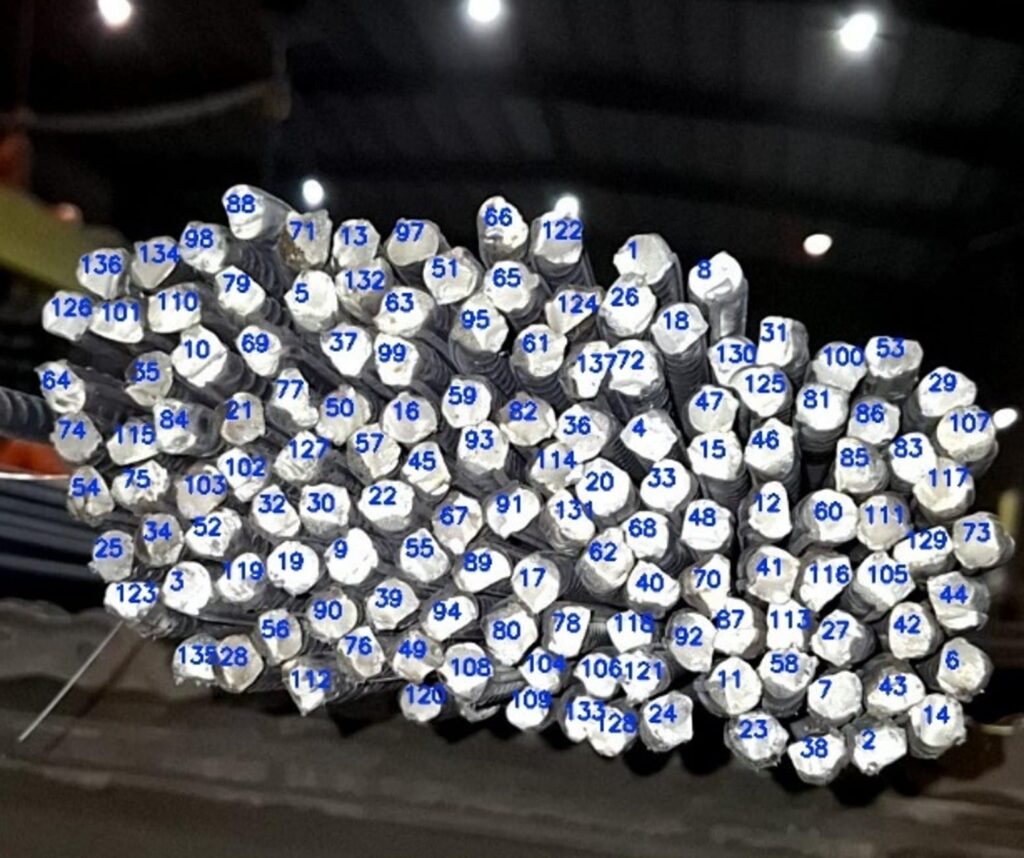

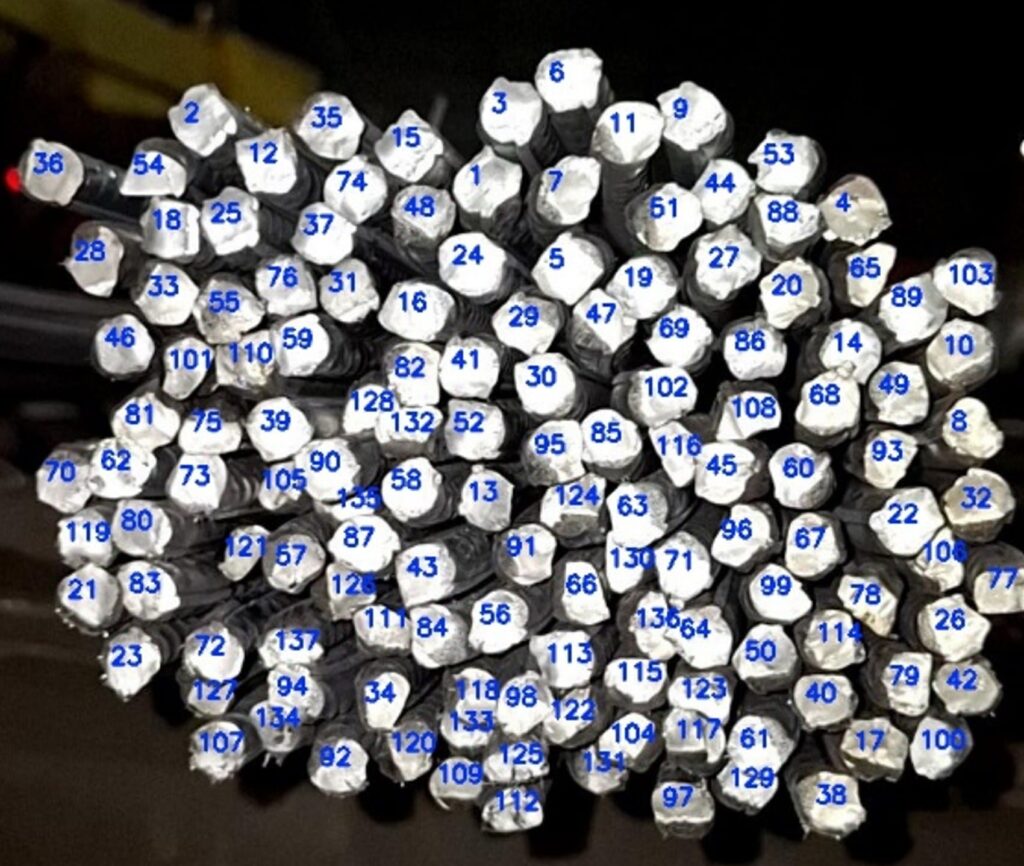

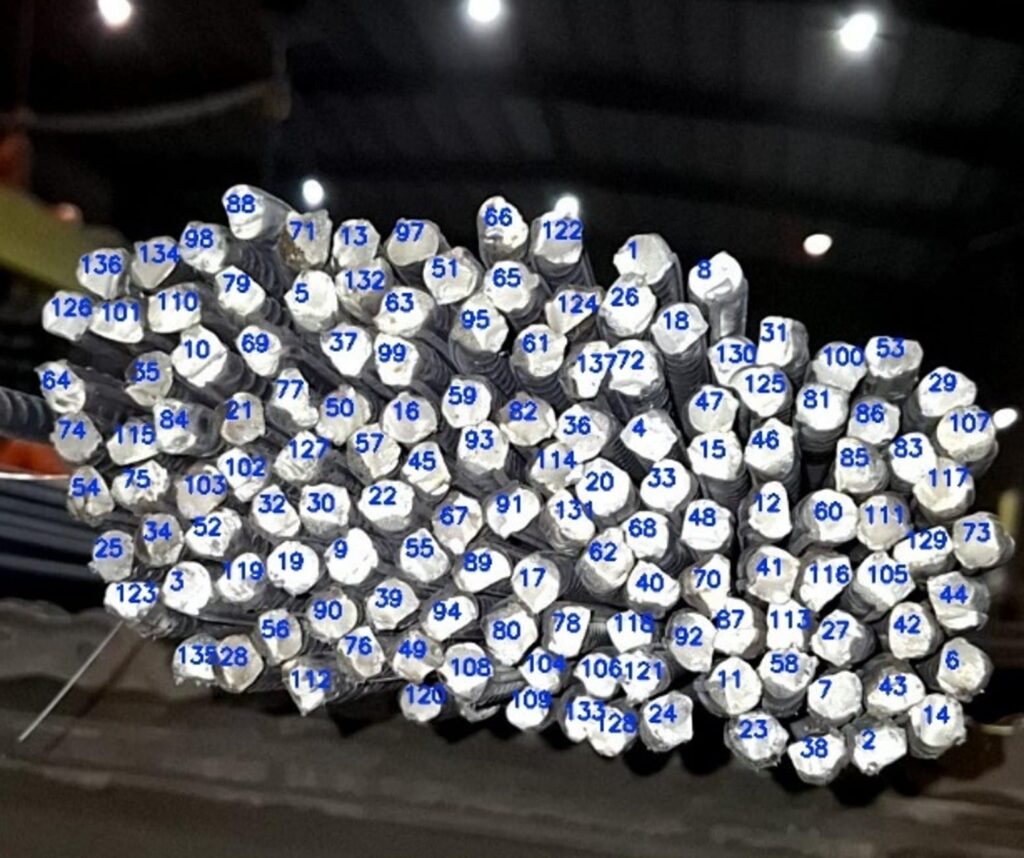

Rebar Counting for Steel Industry

- Problem: Manual counting of rebar bundles is slow, prone to inaccuracies, and creates significant QC bottlenecks, delaying inventory logging and shipping.

- Solution: See.AI™ automates this process with AI-powered counting and inventory management, deployed for publicly listed steel companies.

- Key Results: Clients have achieved a 75% increase in production output, an ~80% reduction in counting time, and significant reduction in paper usage.

- Additional Points: This solution introduces robust product traceability and helps clients meet ESG compliance goals.

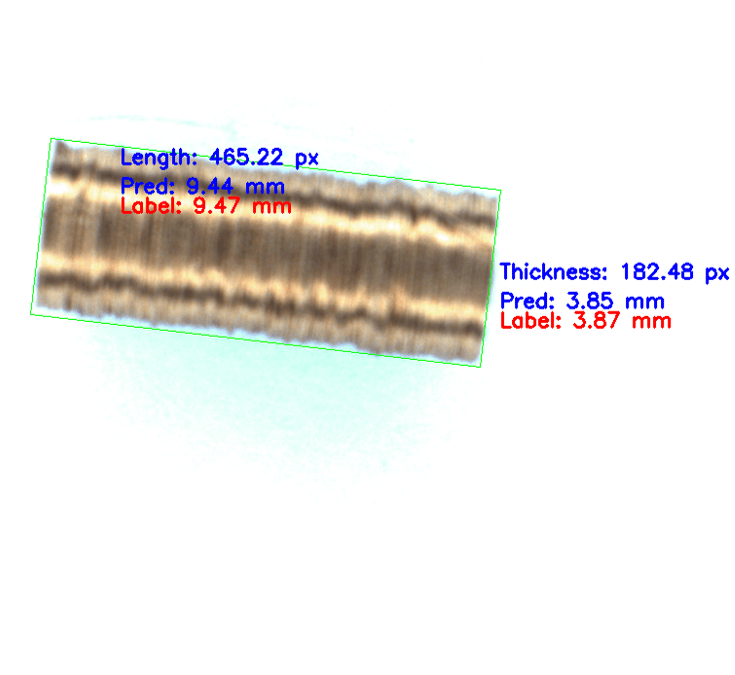

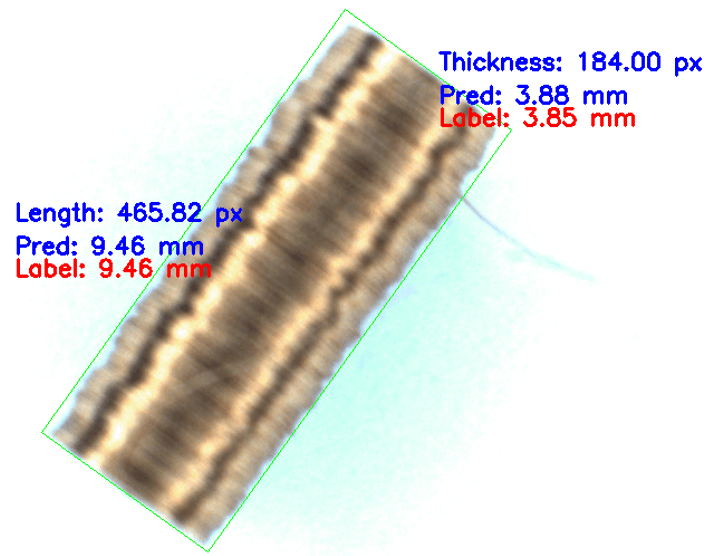

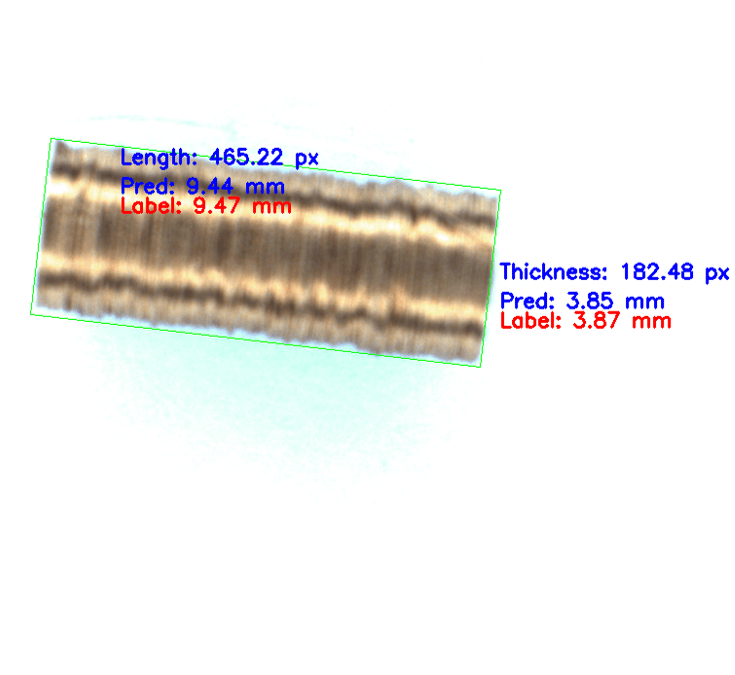

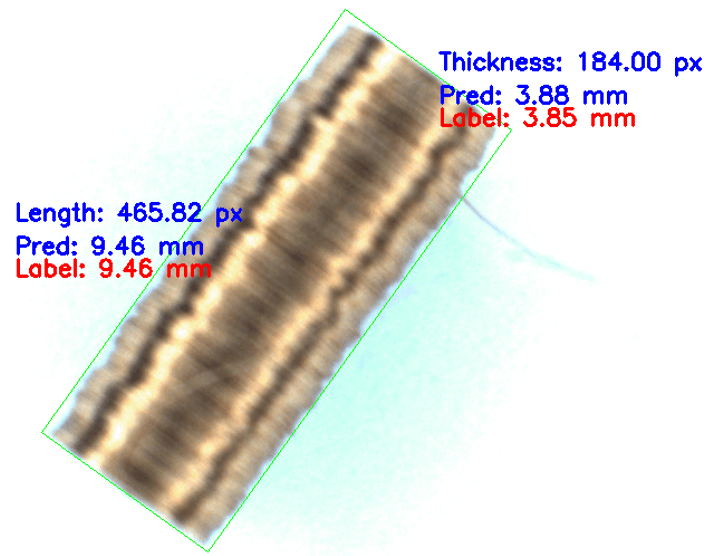

Coil Measurement in Metal Industry

- Problem: Relying on manual tools like vernier calipers or micrometers for copper coil measurement is slow, inconsistent, and a drag on workflow efficiency.

- Solution: See.AI™ is deployed to perform precise, automated measurements, replacing the need for manual tools.

- Key Results: The measurement workflow is simplified, allowing for faster QC and improved overall throughput.

- Additional Points: The solution automatically logs all measurement data into a digitalised system, providing full traceability for every coil produced, eliminating the need for manual data entry.

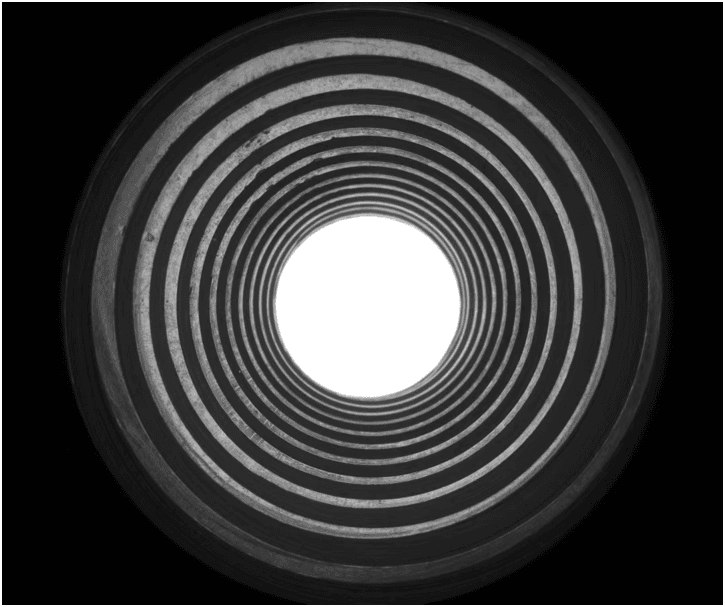

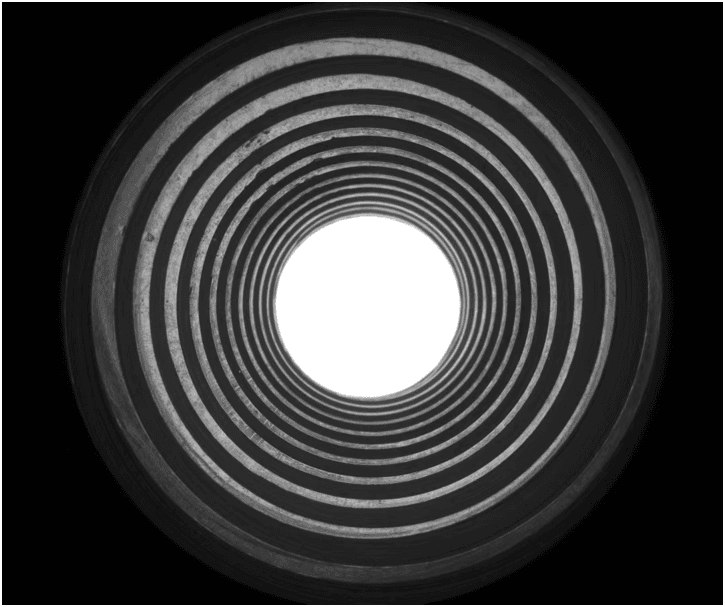

Interior Defect Inspection (Hollow Products)

- Problem: Limited visibility inside hollow products (like metallic pipes or tubes) makes it impossible for standard inspection systems to detect internal flaws like cracks, scratches, burrs, or contamination.

- Solution: We deploy See.AI™ with customised lenses and specialised lighting to capture and inspect the internal surfaces of hollow components.

- Key Results: This enables complete, automated inspection of internal surfaces, catching hidden defects that were previously missed.

- Additional Points: Highlights our technical capabilities in providing customised solutions according to industry specific needs.

Proven Applications

& Use Cases

PRODUCTION & QC PROCESS

Defect Inspection in Semiconductor Industry

- Problem: Existing AOI machines are over-rejecting, resulting in an average yield rate of 90%. Employing human operators to salvage over-rejected units is costly and less sustainable.

- Solution: See.AI™ augments these existing AOI machines to eliminate over-rejection.

- Key Results: We have achieved a 98.5% new yield rate and an 85% reduction in wastage for a publicly listed semiconductor client.

- Lowered CAPEX: Our AI-powered solution can upgrade your existing cameras, allowing you to meet modern requirements without procuring new hardware.

Rebar Counting for

Steel Industry

- Problem: Manual counting of rebar bundles is slow, prone to inaccuracies, and creates significant QC bottlenecks, delaying inventory logging and shipping.

- Solution: See.AI™ automates this process with AI-powered counting and inventory management, deployed for publicly listed steel companies.

- Key Results: Clients have achieved a 75% increase in production output, an ~80% reduction in counting time, and significant reduction in paper usage.

- Additional Points: This solution introduces robust product traceability and helps clients meet ESG compliance goals.

Coil Measurement in

Metal Industry

- Problem: Relying on manual tools like vernier calipers or micrometers for copper coil measurement is slow, inconsistent, and a drag on workflow efficiency.

- Solution: See.AI™ is deployed to perform precise, automated measurements, replacing the need for manual tools.

- Key Results: The measurement workflow is simplified, allowing for faster QC and improved overall throughput.

- Additional Points: The solution automatically logs all measurement data into a digitalised system, providing full traceability for every coil produced, eliminating the need for manual data entry.

Interior Defect Inspection

(Hollow Products)

- Problem: Limited visibility inside hollow products (like metallic pipes or tubes) makes it impossible for standard inspection systems to detect internal flaws like cracks, scratches, burrs, or contamination.

- Solution: We deploy See.AI™ with customised lenses and specialised lighting to capture and inspect the internal surfaces of hollow components.

- Key Results: This enables complete, automated inspection of internal surfaces, catching hidden defects that were previously missed.

- Additional Points: Highlights our technical capabilities in providing customised solutions according to industry specific needs.

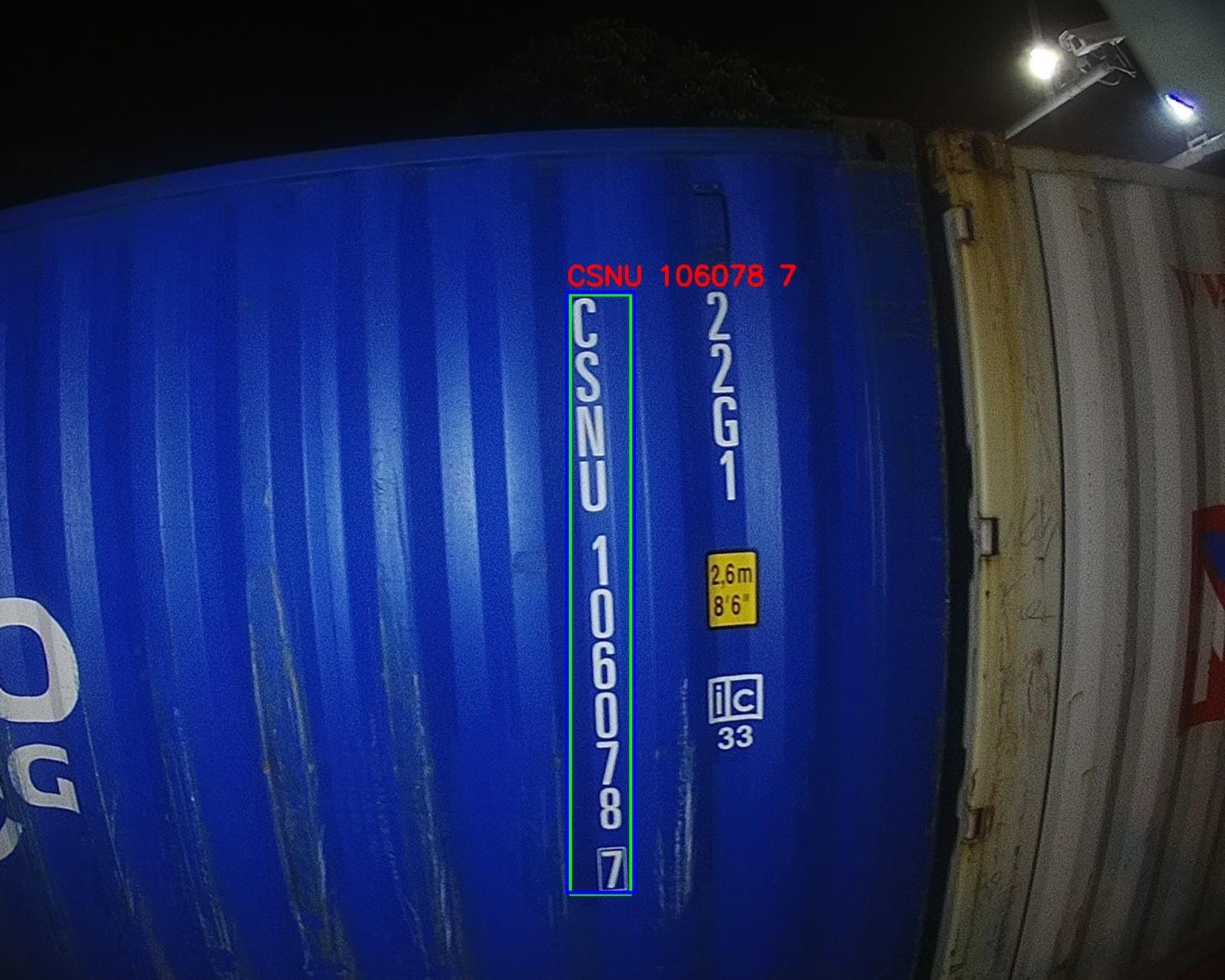

Proven Applications & Use Cases

SMART CCTV SURVEILLANCE

Proactively enforces safety by automatically monitoring existing CCTVs for PPE violations,, eliminating inefficient manual policing.

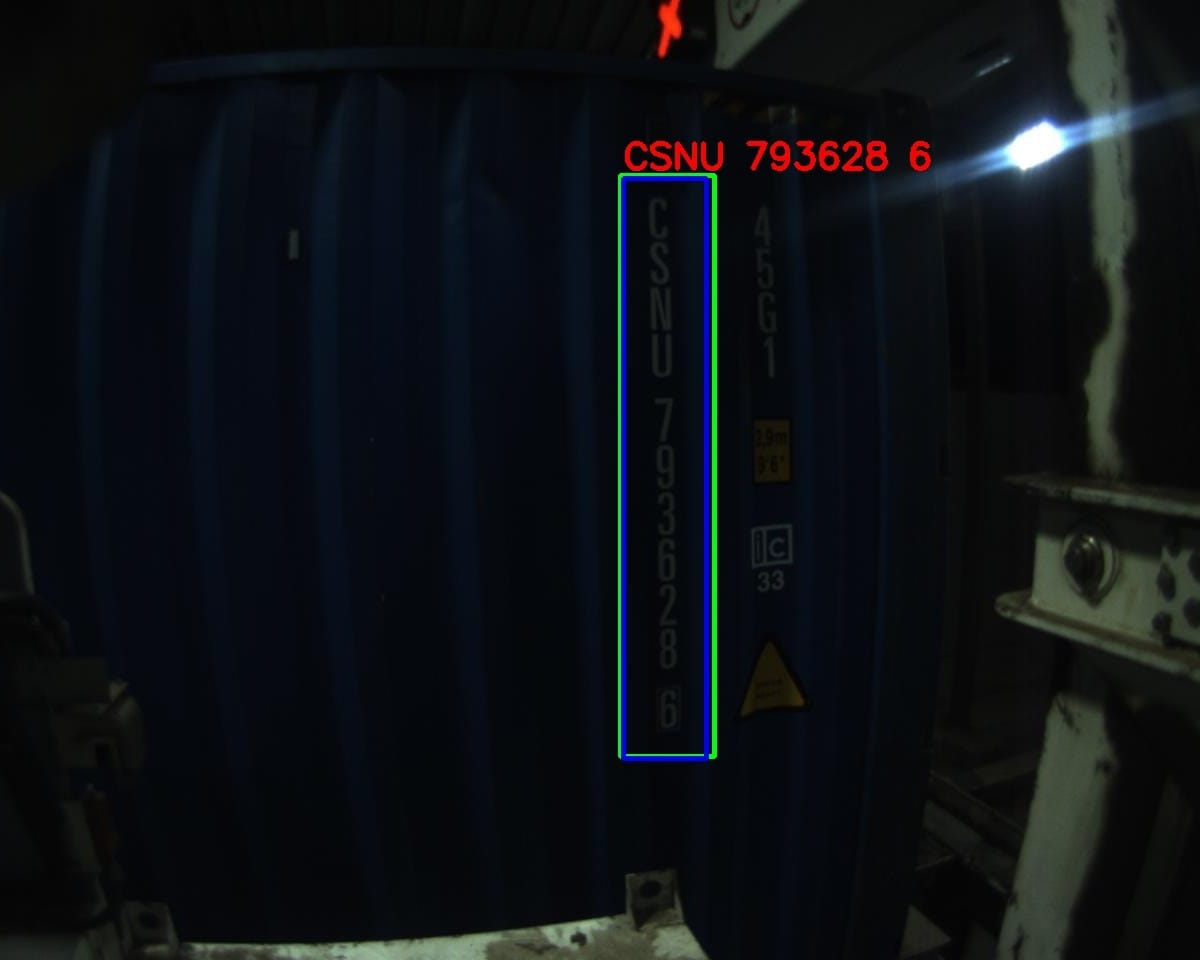

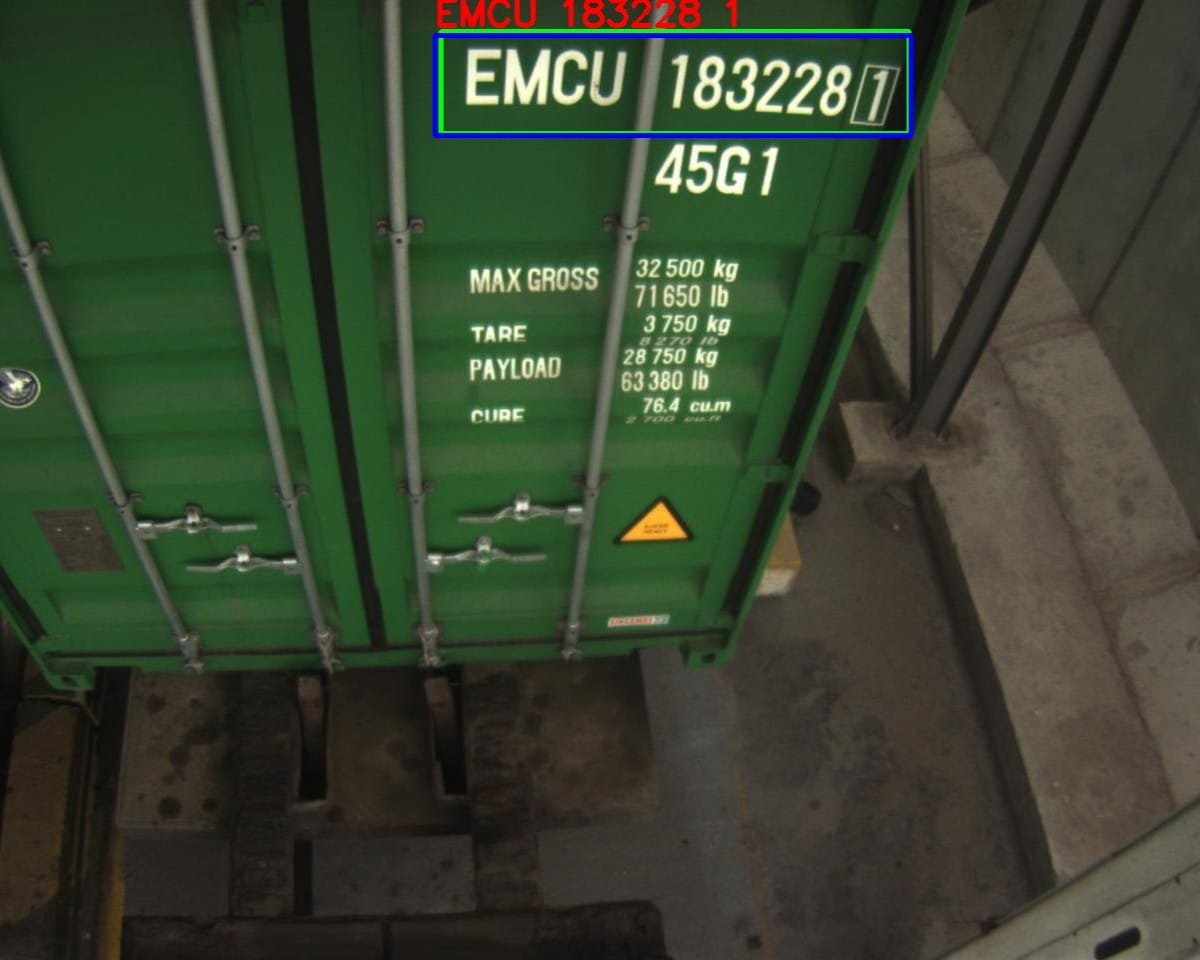

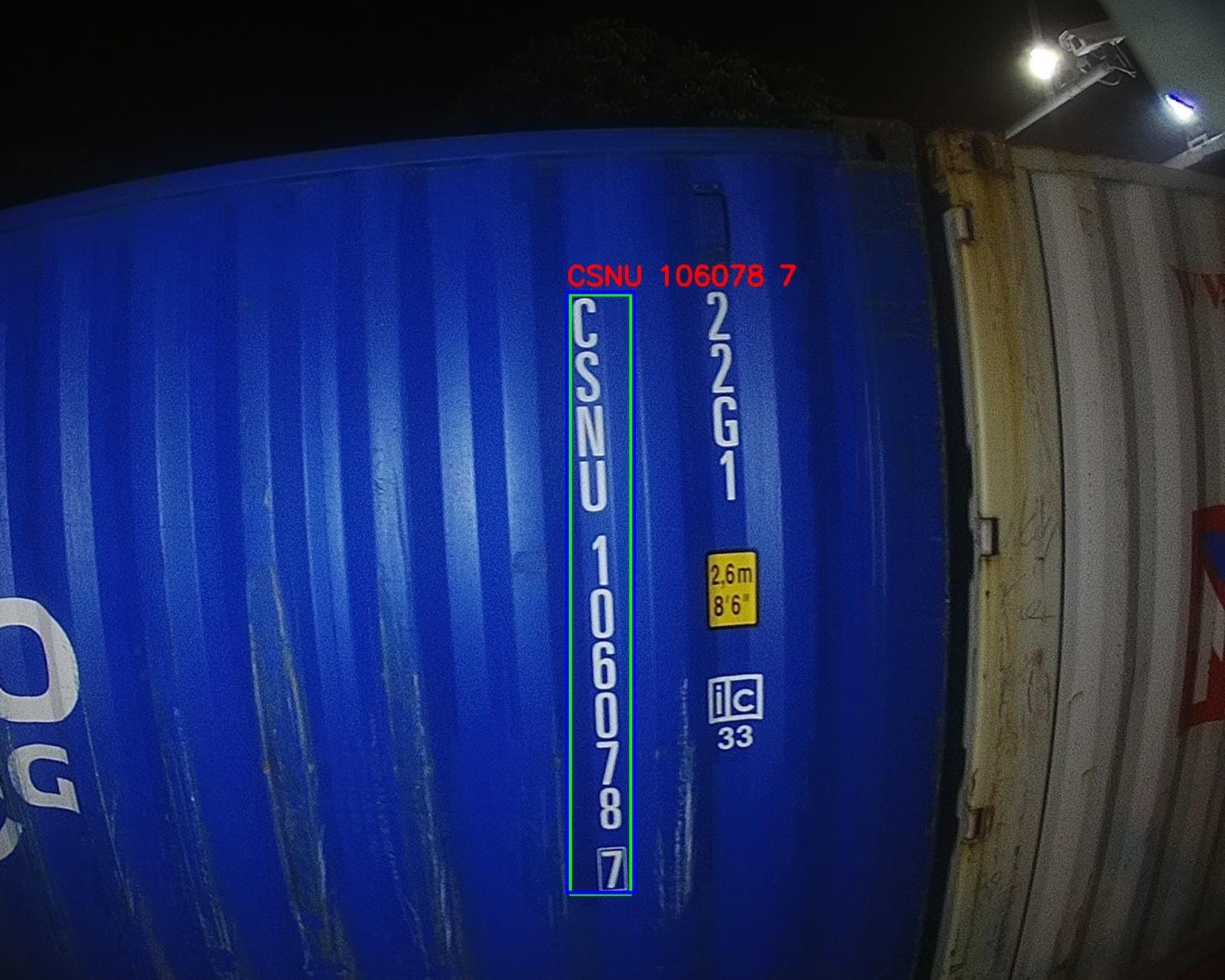

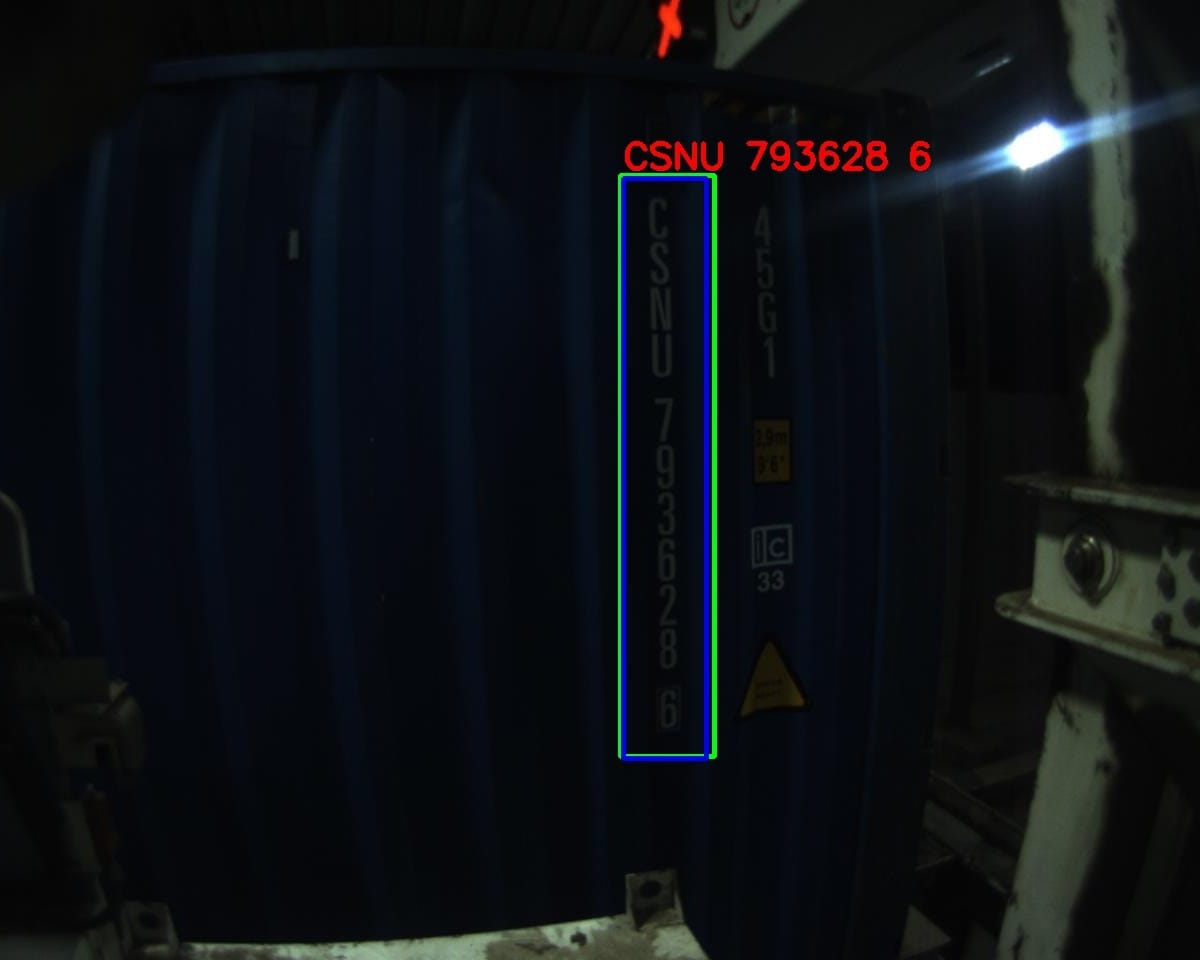

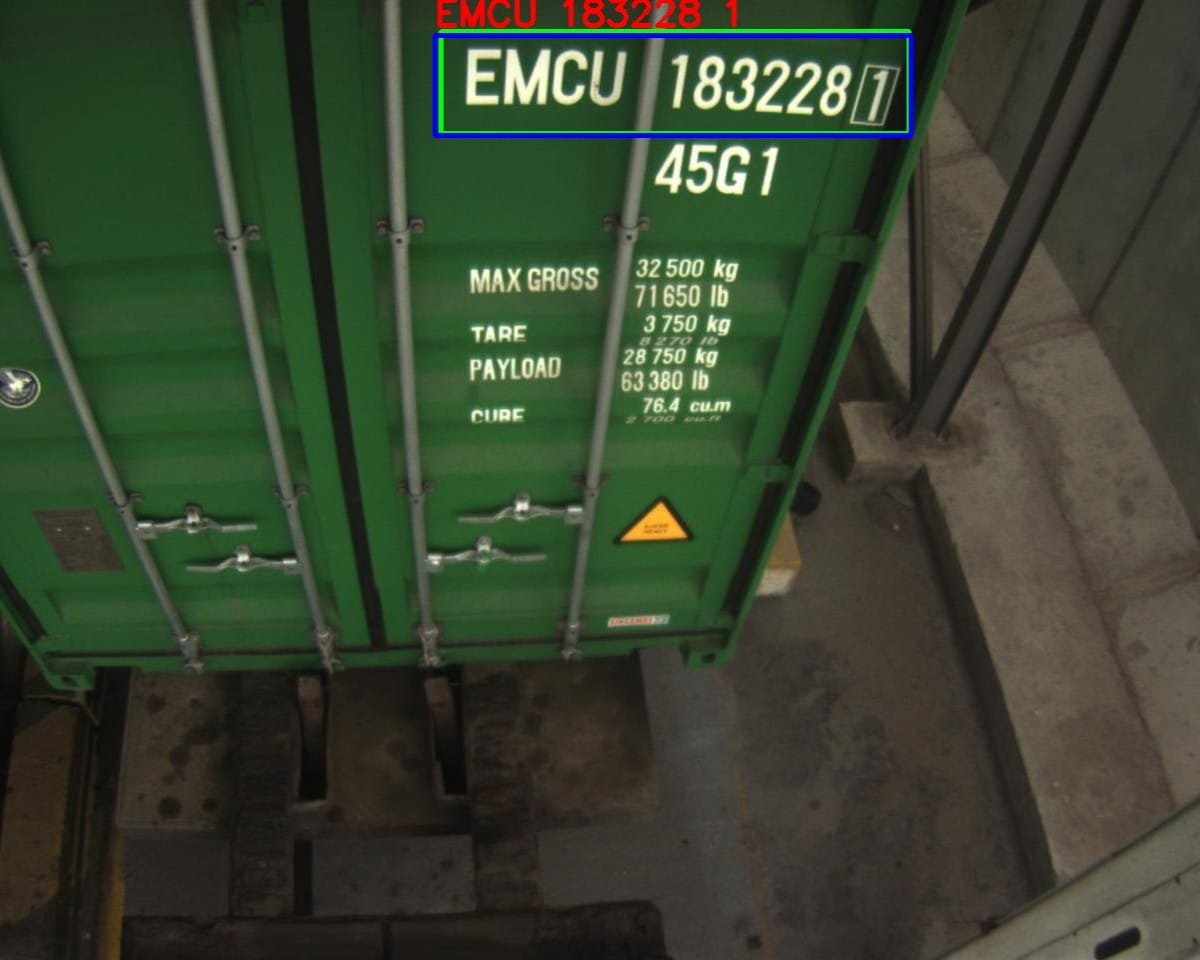

Automatically detects and extracts cargo container ID for immediate data logging and real-time traceability, eliminating errors from traditional manual logging.

Automatically detects SOP breaches, like phone usage in restricted zones, to enforce safety protocols and reduce accident risks without manual intervention.

Provides objective, real-time insights by monitoring employee productivity metrics, such as active vs. idle time , to help managers optimise workflows.

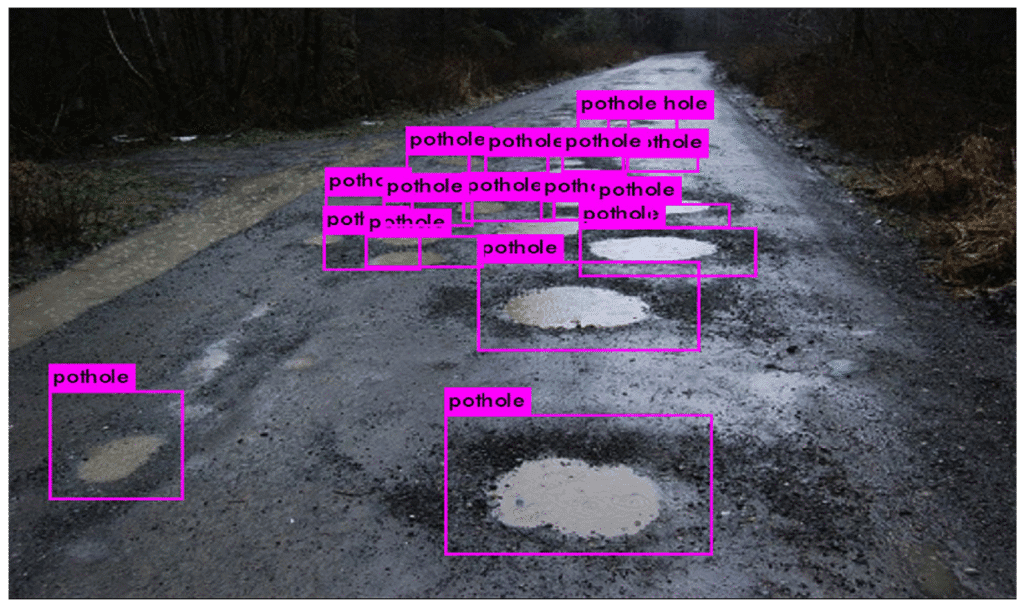

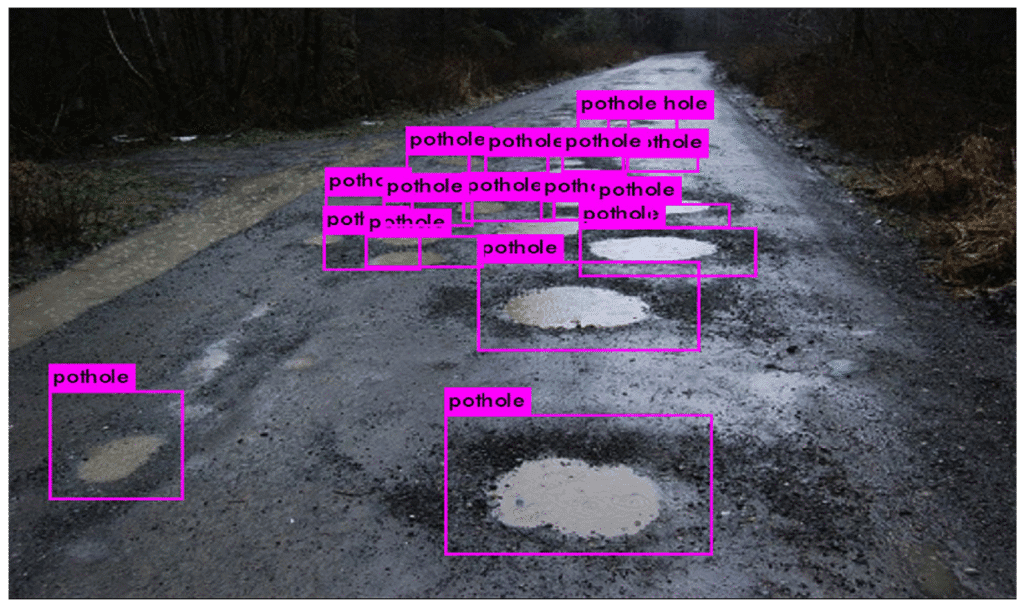

Proactively monitors road infrastructure by using cameras to automatically detect and log potholes and other road damage, enabling faster repairs and maintenance.

Proven Applications

& Use Cases

SMART CCTV SURVEILLANCE

Proactively enforces safety by automatically monitoring existing CCTVs for PPE violations,, eliminating inefficient manual policing.

Automatically detects and extracts cargo container ID for immediate data logging and real-time traceability, eliminating errors from traditional manual logging.

Automatically detects SOP breaches, like phone usage in restricted zones, to enforce safety protocols and reduce accident risks without manual intervention.

Provides objective, real-time insights by monitoring employee productivity metrics, such as active vs. idle time , to help managers optimise workflows.

Proactively monitors road infrastructure by using cameras to automatically detect and log potholes and other road damage, enabling faster repairs and maintenance.

Ready to Solve Your Problem?

See a use case that matches your needs, or have a unique challenge? Contact our team of AI Solutions Consultants to learn more about how we can deliver tangible results for your business.