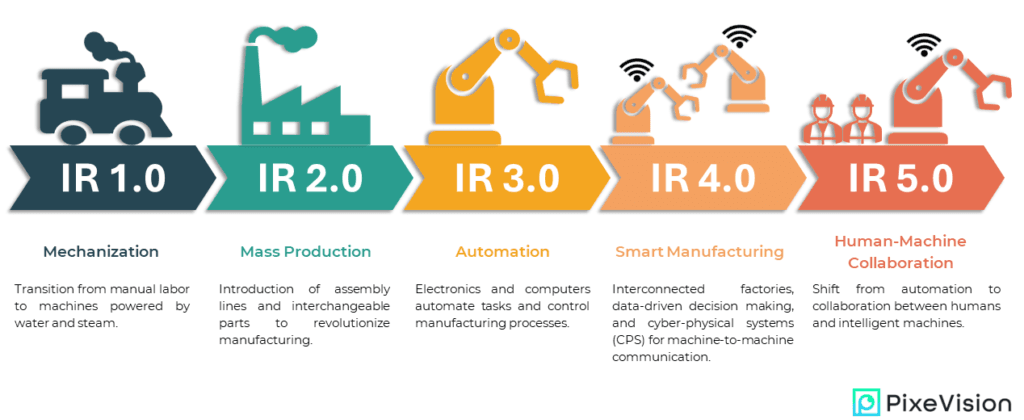

The manufacturing landscape is in the midst of a paradigm shift. Industry 4.0, the “Smart Factory” revolution, introduced automation, big data analytics, and hyper-connected production lines. While groundbreaking, it often positioned machines as powerful tools, operating largely independent of human input.

Industry 5.0, however, marks a shift – a move towards a true human-machine partnership.

Industry 4.0: The Age of the Machine “Workforce”

Imagine a factory floor bustling with robots performing repetitive tasks flawlessly. This was the essence of Industry 4.0. Here’s what defines it:

- Unleashing the Power of Automation: Robots and smart machines took centre stage, streamlining production lines and achieving impressive levels of efficiency.

- Data as the New Fuel: Real-time data collection and analysis fuelled intelligent automation, predictive maintenance, and data-driven optimization.

- The Rise of Cyber-Physical Systems (CPS): The physical world of manufacturing merged with the digital realm, allowing for machine-to-machine communication and self-optimization.

However, several limitations still arose:

- Humans as Observers, Not Collaborators: While AI and automation played a crucial role, humans often became passive observers, monitoring processes rather than actively participating in decision-making.

- Data Silos & Integration Challenges: Connecting diverse systems and ensuring data consistency across the manufacturing ecosystem remained a hurdle.

- Workforce Concerns: The rapid pace of automation raised anxieties about job displacement and the need for entirely new skill sets.

Industry 5.0: Where Humans Join the Centre Stage

Industry 5.0 builds upon Industry 4.0’s foundation but adds a critical element: Human-Machine Collaboration.

Imagine the factory floor transformed, with skilled conductors and machines working in tandem, leveraging their unique strengths and adding a layer of human expertise and judgment within the existing automation system.

Why Collaboration is Key in Industry 5.0:

- Domain Expertise: Experienced operators bring a wealth of knowledge about the products, manufacturing processes, and potential failure modes – invaluable for training and refining AI algorithms to achieve higher reliability.

- Meticulous Decision-Making: Human judgment is critical for analyzing complex situations, interpreting ambiguous data, and making informed decisions about defects or production issues that require human intervention.

- Continuous Learning Loop: Human feedback on AI performance fuels continuous improvement, allowing the system to adapt and learn from real-world scenarios, ultimately leading to a more robust manufacturing ecosystem.

- Reduced Costs & Increased ROI: The combined power of AI and human expertise can lead to optimized processes and resource allocation, maximizing efficiency and cost savings.

Why Embracing Industry 5.0 is the Future:

- Enhanced Accuracy & Efficiency: The combined power of AI and human expertise leads to a more robust QC process with fewer missed defects and faster decision-making.

- Increased Adaptability: The collaborative approach allows for adapting to changing market demands, new product introductions (NPI), and evolving quality standards with greater flexibility.

- Empowered Workforce: Industry 5.0 creates opportunities for upskilling and reskilling the workforce to work alongside AI for higher-level tasks, leading to a more empowered and valuable workforce, rather than job displacement.

What’s Next – The Future of the Human-Machine Symphony

The future of Industry 5.0 lies in further refining the human-machine collaboration. Here are some exciting possibilities:

- Advanced AI & Machine Learning: More sophisticated AI capabilities will enable deeper collaboration with human inspectors, leading to more intelligent and autonomous systems that complement human expertise.

- Enhanced Human-AI Interface Design: User interfaces will become more intuitive and personalized, allowing for seamless interaction and data exchange between humans and machines.

- Focus on Sustainability & Ethical Manufacturing: Industry 5.0 can be a catalyst for sustainable manufacturing practices and ethical considerations within human-machine collaboration.

So far, the concept of Industry 5.0 has not been widely discussed. Many businesses are still focused on implementing Industry 4.0 technologies or are still in the early stages of adoption. By embracing Industry 5.0 and its focus on human-machine partnership, businesses can unlock a new era of manufacturing excellence –

One that is efficient, adaptive, and empowers the human workforce to be the conductor of this powerful symphony.